Intelligent Manufacturing

The team members are from well-known enterprises in the industry, with more than 10 years of industrial experience. The team has long been working with customers in Europe, America, and Japan. And very familiar with the needs and ideas of foreign customers.

We are also very strict in the selection of supply chains, and our long-term relationship has given us certain advantages in terms of price, delivery, and service, and some common automation brands have cooperated with us. For example, Siemens, Festo, Keyence, Omron, Schneider, Mismi, Pilz, SMC, SICK, and many more.

We are particularly good at providing customized total automation solutions for customers in the automotive industry, from jigs and fixtures to equipment, testing equipment, and automated production lines, robotics applications, etc.

We have successfully helped a number of clients to deliver projects

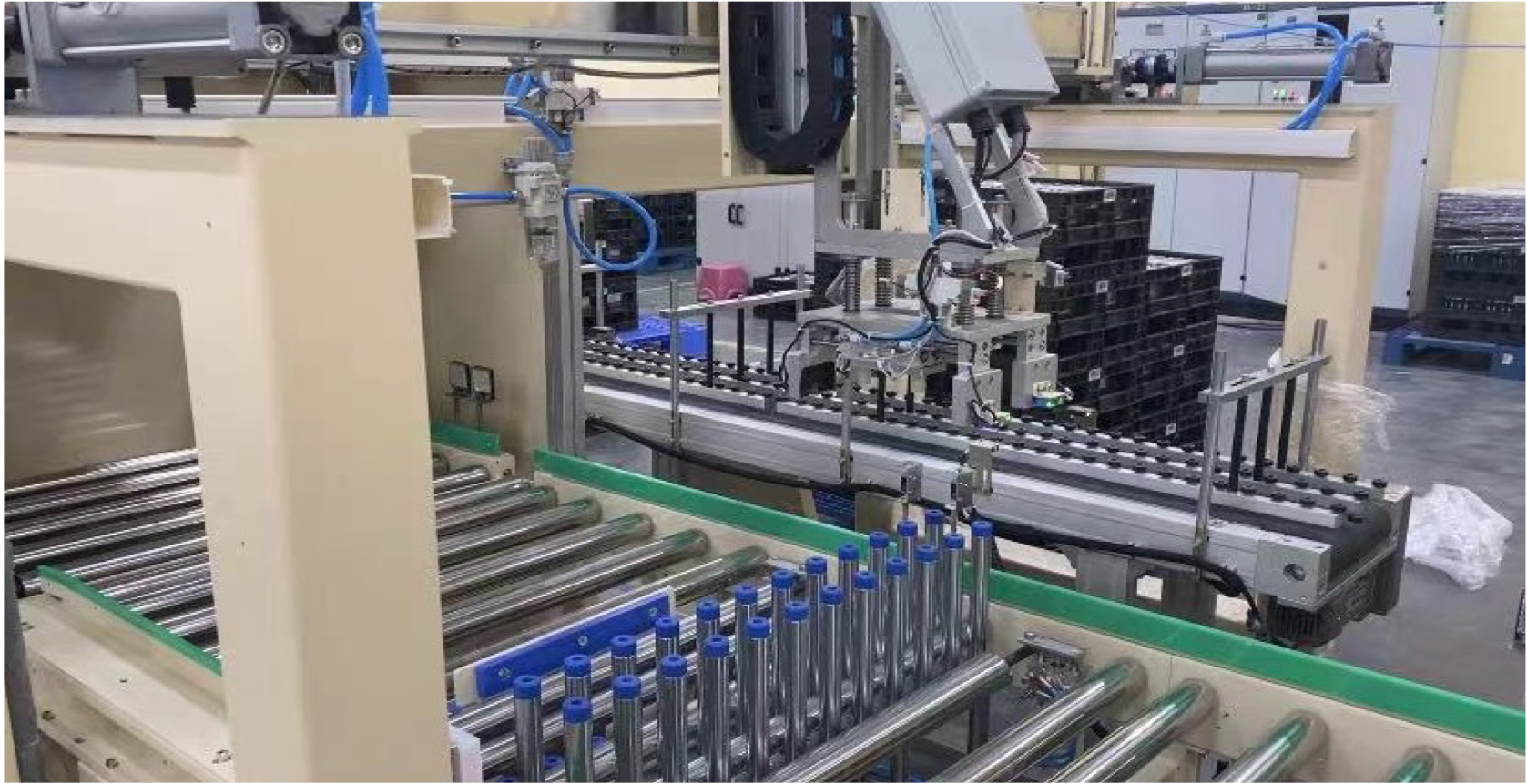

The projects we have completed include fully automatic measuring machines for the automotive industry, environmental protection equipment, conveyor lines, battery module caching machines for the new energy lithium industry, and battery module sorting and grouping machines.

We have also completed steering system assembly and testing equipment, balance bar assembly equipment, damper assembly equipment, boom line assembly equipment, Geely car exchange station, and other projects.

We have a well-established project management process

Pre-Sales Solution

Providing Solutions

Quotation

Contract Signing

Detailed Solution Design

Refinement of the Solution

2D/3D Design

Design Review

Sourcing Manufacturing

Sourcing of Standard Parts

Workpiece Fabrication

Production Commissioning

Equipment Assembly

Commissioning and Pre-acceptance

After Sales Service

On-site Installation and Commissioning

Final Acceptance and After-Sales Support

On Demand Training

Training Per Customer's requirement

Project Showcases

Examples of the Intelligent manufacturing projects we have completed

Fully Automatic Measuring Machines

Precision measurement of position and dimensions, mainly for components in the automotive industry, using a Siemens control system and standard upper computer measurement software.

Lithium Industry

- PACK conveying line, involving 3-axis trusses, conveying rollers, etc.

- Battery module caching machines

- Battery module sorting and stacking machines